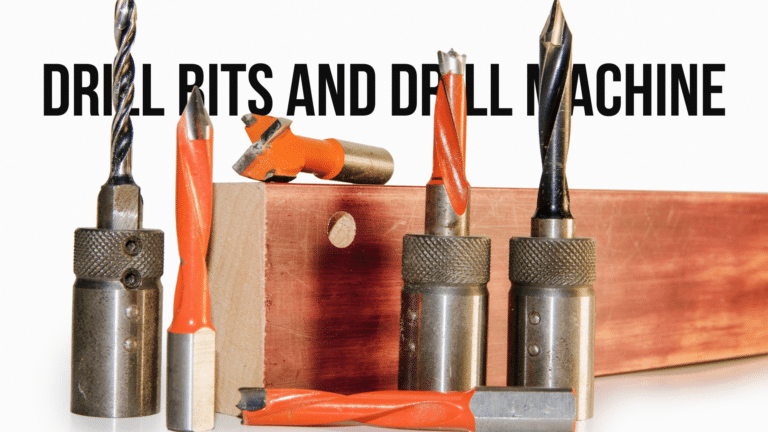

WHAT IS DRILL BITS AND DRILL MACHINES

Drill bits and drill machines are essential tools in various industries and DIY projects, serving the fundamental purpose of creating holes in materials like wood, metal, concrete, and plastic. Drill bits are the cutting tools attached to drill machines, designed with specific shapes, materials, and sizes to suit different applications. They come in various types, including twist bits, spade bits, hole saws, and masonry bits, each tailored for different materials and hole sizes.

Drill machines, on the other hand, are power tools that provide the necessary force and rotation to drive the drill bits into the material, enabling efficient and precise hole drilling. From simple home repairs to large-scale construction projects, drill bits and drill machines play a crucial role in achieving accurate and consistent results. Understanding the characteristics and functionalities of these tools is essential for selecting the right combination to meet specific project requirements and ensure successful outcomes.

Types of Drill Bits

Twist Drill Bits: These are the most common type of drill bits, featuring a spiraled cutting edge for drilling into various materials such as wood, metal, plastic, and more.

Twist Drill Bits: These are the most common type of drill bits, featuring a spiraled cutting edge for drilling into various materials such as wood, metal, plastic, and more.Masonry Drill Bits: Designed for drilling into tough materials like concrete, brick, and stone, these bits often have a carbide tip for increased durability.

Spade Drill Bits: Also known as paddle bits, these are used for drilling large holes in wood. They have a flat spade-shaped head with a central point for accurate positioning.

Forstner Drill Bits: Ideal for woodworking, these bits create flat-bottomed holes and are perfect for drilling pocket holes and overlapping holes.

Step Drill Bits: These bits have a conical shape with multiple stepped-diameter cutting edges, allowing for drilling holes of different sizes without needing to change the bit.

Countersink Drill Bits: Used to create a conical recess to accommodate the head of a screw, these bits are essential for woodworking and metalworking.

Drill Bit Materials

- High-Speed Steel (HSS): Commonly used for general-purpose drilling in wood, metal, and plastic.

- Carbide: Known for its hardness and heat resistance, carbide drill bits are suitable for drilling hard materials like concrete and masonry.

- Cobalt: With a high resistance to heat, cobalt drill bits are ideal for drilling tough materials such as stainless steel.

Understanding Drill Machines

A drill machine, also known as a drill press, is a versatile tool used for drilling holes in various materials. It consists of a base, column, table, spindle, and drill head, and is available in different sizes and configurations to suit different applications.

Types of Drill Machines

Bench Drill Press: Mounted to a workbench or stand, this type of drill press is suitable for small to medium-sized workpieces and offers precision and stability.

Magnetic Drill Press: Used for portable drilling on large or unwieldy workpieces, these machines utilize a magnetic base to secure the drill to the workpiece.

Radial Drill Press: With a movable spindle, these drill presses are ideal for drilling large and heavy workpieces, offering flexibility and precision.

Upright Sensitive Drill Press: Employed for light-duty drilling tasks, these machines are equipped with a tilting table and are suitable for small workshops and precision drilling.

Features and Functionalities

- Variable Speed Control: Many modern drill machines offer variable speed settings, allowing the user to adjust the drilling speed to suit the material being worked on.

- Depth Stop: This feature enables the user to set the drilling depth, ensuring consistency across multiple workpieces.

- Swing: The distance from the center of the spindle to the nearest edge of the column, determining the maximum size of workpiece the drill press can accommodate.

Safety Measures When Using Drill Machines and Drill Bits

Drilling operations, whether using drill machines or handheld drills, require strict adherence to safety protocols to prevent accidents and injuries. Here are some essential safety measures to consider

Personal Protective Equipment (PPE)

- Eye Protection: Always wear safety glasses or a face shield to guard against flying debris, particularly when drilling metal, masonry, or wood.

- Hearing Protection: In environments with high noise levels, such as when drilling through tough materials, use earplugs or earmuffs to protect your hearing.

Work Area Safety

- Secure Workpiece: Ensure the workpiece is firmly secured using clamps or a vice to prevent movement during drilling, reducing the risk of accidents.

- Clear Work Area: Keep the work area clean and free from obstacles to avoid tripping hazards and ensure unobstructed movement.

Drill Machine Safety

- Read the Manual: Familiarize yourself with the drill machine’s manual to understand its specific safety features, operational instructions, and maintenance requirements.

- Inspect the Machine: Before use, check the drill machine for any damage or defects, paying particular attention to the power cord, switches, and safety guards.

Drill Bit Safety

- Use the Right Bit: Ensure that the drill bit is suitable for the material being drilled. Using the wrong type of bit can lead to breakage, kickback, or inefficient drilling.

- Securely Fasten the Bit: Always tighten the drill bit securely in the chuck to prevent slippage during operation.

General Safety Practices

- Unplug Power: Before changing drill bits or making adjustments to the drill machine, ensure that it is unplugged or the power source is switched off to prevent accidental activation.

- Proper Technique: Maintain a stable stance and grip on the drill machine, keeping hands away from the drill bit and moving parts during operation.

- Avoid Loose Clothing and Jewelry: Ensure that clothing, jewelry, and accessories are secured to prevent entanglement with the drill or workpiece.

Emergency Preparedness

- Know the Emergency Stop: Familiarize yourself with the emergency stop feature of the drill machine and its location in case of an unexpected situation.

- First Aid Kit: Keep a well-stocked first aid kit in the vicinity of the work area to address minor injuries promptly.

Training and Supervision

- Training: Ensure that anyone operating a drill machine or using drill bits has received adequate training in their safe and proper use.

- Supervision: For inexperienced operators, supervision by someone with expertise in drilling operations is advisable until proficiency is attained.

Conclusion

Drill bits and drill machines are indispensable tools in a wide range of industries and applications. Understanding the different types of drill bits, materials, and functionalities, as well as the various types of drill machines and their features, is crucial for achieving efficient and precise drilling operations. Whether for professional or DIY use, having a comprehensive knowledge of drill bits and drill machines is essential for safe and effective drilling.

FREQUENTLY ASKED QUESTION

Where can I find more information about drill bits and drill machines?

You can find additional information and resources online, including manufacturer websites, instructional videos, and DIY forums. Additionally, consulting with experts at hardware stores or attending workshops can provide valuable insights and guidance.

Are there safety precautions I should follow when using drill bits and machines?

Yes, always wear appropriate safety gear such as safety glasses and ear protection when operating drill machines. Secure workpieces firmly and use clamps or a vice to prevent slipping. Follow the manufacturer’s instructions and guidelines for safe operation of both drill bits and machines.

Can I use drill bits and machines for woodworking projects?

Yes, drill bits and machines are commonly used in woodworking projects for tasks such as drilling pilot holes, creating countersinks, and assembling furniture and cabinetry.

How can I maintain my drill bits and drill machine?

Keep drill bits clean and sharp by regularly removing debris and sharpening dull edges. Lubricate moving parts of the drill machine as needed and store both drill bits and machines in a dry, clean environment to prevent rust and corrosion.

Can drill bits be used with different materials?

Yes, drill bits are designed to work with a variety of materials. However, it’s essential to use the appropriate type of drill bit for each material to achieve the best results and prolong the life of the bit.

How do I select the right drill machine for my needs?

Determine the type and size of the projects you’ll be working on, as well as your preferred level of portability and power source (corded or cordless). Consider factors such as drill speed, chuck size, and additional features like variable speed control and built-in lights.

What are drill machines?

Drill machines, also known as drills or drill presses, are power tools used to provide the necessary force and rotation to drive drill bits into materials. They come in various sizes and configurations, including handheld drills and stationary drill presses.

How do I choose the right drill bit for my project?

Consider factors such as the material you’re drilling into, the desired hole size, and the type of drill machine you’ll be using. Match the characteristics of the drill bit to the requirements of your project for optimal results.

What are the types of drill bits available?

There are several types of drill bits, including twist bits, spade bits, hole saws, masonry bits, auger bits, and Forstner bits. Each type is designed for specific materials and hole sizes.

What are drill bits?

Drill bits are cutting tools used in conjunction with drill machines to create holes in various materials such as wood, metal, concrete, and plastic. They come in different types, sizes, and materials to suit different applications.